Welcome to 2022!

Leave a CommentWow – here we are, starting yet ANOTHER New Year. Some of us are still getting used to writing “2021” on our checks, and many of us couldn’t be happier putting last year behind us.

There’s no question the past two years have been challenging. Our company and our city experienced the damage of a Category 4 Hurricane called a “Derecho” in mid 2020. No one would ever have thought a hurricane would hit IOWA. While working through that, we also had to find creative ways to navigate through the pandemic and that has been a challenge as well. We’ve had staff out due to Covid, and we’ve been in the middle of supply chain issues with unheard-of lead times that have put a strain on us all.

In many regards, we could have the same negative thoughts and “doom and gloom” that so many have had. This is not to say that things have been easy the last couple of years, but we choose to look at how fortunate we are and how blessed we have been. We are so thankful for the team we have at MPRC and their commitment and dedication to our customers. The reality is, through all of these struggles, we have ended 2021 as one of our best and most profitable fiscal years in our companies’ history.

How does this happen when we know that everyone is short-staffed, lead times are triple what they used to be, and raw material costs continue to go up in what seems like monthly increases? How can a company combat these things and still come out profitable and with record numbers?

The answer is: we stretch ourselves. We have become even more innovative and self-reliant, increasing our overall capacity of in-house rubber molded components. We’ve increased our commitment to marketing and letting our customers and potential customers know more about the products and services we offer, and what sets MPRC apart from our competition. We’ve invested in a new website that will serve as an incredible resource for our customers for both technical and current industry news, including readily available product flyers for download and product videos.

Great things are happening at MPRC, and we are excited about what 2022 will bring. We are bringing on new staff to continue to bring the quality and service our customers have come to expect. Thank you for your continued business and trust in us as your fluid sealing specialist.

Best regards,

Josh Hale

President

Master Packing & Rubber Company

IMPORTANT ANNOUNCEMENT FROM MPRC!

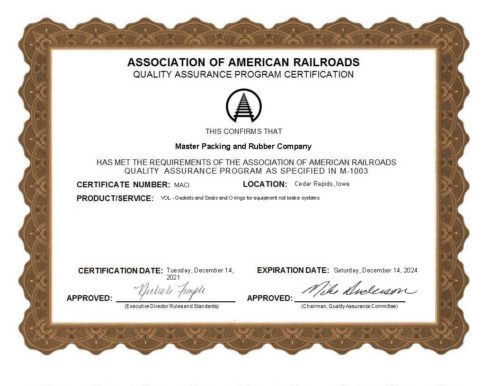

Leave a CommentIT’S OFFICIAL:

MPRC, a manufacturer of seals and gaskets for Locomotives and Rail Cars is AAR M1003 Certified! We proudly add that to our ISO 9001-2015 Certification– and as always, we THANK YOU for your business. As a reminder, MPRC manufactures right here in the good ole’ USA!

Call MPRC today at 800-397-3429, or email our sales team: sales@mprcseals.com

Let us assist you with quality seals and gaskets for all your Locomotive and Rail Car needs!

“Set it and forget it!” with MPRC’s Flex-Tex High-Performance Flange Sealant!

Leave a Comment

Have you ever found yourself in a bind where you need something to seal a door, a flange, or anything quickly- but don’t have time to wait for trim seal, extrusion, or cut gasket? It happens. Maybe you’ve found yourself thinking, “I sure wish there was something I had in my toolbox or on my storeroom shelf that I could always have on hand to seal what’s needed.” Well, there’s good news: MPRC has just what you need!

Make no mistake: MPRC is serious about QUALITY. We only stand behind the very best materials. It’s what our customers have come to expect and what we expect of ourselves. We are proud to offer this Premium Flange Sealant made in the USA!

Flex-Tex comes in a variety of sizes in a quick and easy-to-use spool. It’s got a “sticky-back” that allows it to be applied easily to your working surface. Are you working in an environment where your seal needs to be FDA compliant, handle most common chemicals, and withstand higher temps than standard rubber materials? Is the surface you’re working with rough, pitted, scratched, or damaged? Need a door seal or a material that will compress and seal like a champ? Set it and forget it!- Flex-Tex has you covered!

MPRC’s Flex-Tex is THE “Go-to Sealant” for emergencies and unexpected shut-downs. It should be part of every Maintenance Technician’s toolbox, storage bin, or warehouse. We’ve got the sizing you need- in stock and ready to ship. Call us today at 800-397-3429 or email our sales team at: sales@mprcseals.com to help you stay ahead of the game!

*For more technical data regarding our Flex-Tex material, please visit*: https://www.mprcseals.com/products/expanded-ptfe/

MPRC Fuel Bowl Seal

Leave a CommentWhat sets MPRC apart from other gasket suppliers? One of our main strengths is not only the ability to custom cut virtually any gasket, but we also custom mold a wide variety of rubber components. Fully molded parts, quality controlled from start to finish, made in-house- right here in the USA! One of the many advantages of fully-molded parts from MPRC is not only exceptional quality, but fast turnaround. MPRC can produce the parts, and get them to you quickly. With the current state of supply issues and excessive lead times, this can be a game-changer. Check out below how MPRC is molding our Fuel Bowl Seal and improving the performance, safety, and life-cycle of our customer’s equipment.

MPRC Fuel Bowl Seal

Part #0-EM8104055-CGO

Fuel Filter assemblies are commonly equipped with flat-black (Nitrile) gaskets. During engine operation, clevis thumb screws will loosen from engine vibration, and these flat gaskets will eventually show some fretting deterioration- both causing leaking. One area of importance is centering the bowl into the flat gasket. If vibration through the filter body contacts the glass bowl, it can fracture and crack, and you’ve got a real problem on your hands. The glass bowls also can be moved or placed off-center and can cause unnecessary leaks. With the fuel system under pressure, these failures can contribute to personnel safety issues, fire, and equipment damage.

MPRC was challenged with fixing this sealing issue and creating a seal that would help with installation by centering the fuel bowl through the seal, preventing the bowl from ever contacting the fuel block. The MPRC Fuel Bowl seal was designed using our proprietary Chemours Viton™ compound which we believe is simply unmatched in the industry. Specially molded to accept the glass bowl sealing surface, including additional grooves that mate with the fuel filter assembly body- all designed to absorb engine vibrations and protect the fuel bowl. This secure fit and sealing ability contribute to a safe environment and operation of your equipment.

Reach for the “Gold Standard” today- the MPRC Fuel Bowl Seal! Molded in-house at our Cedar Rapids, IA headquarters.

Contact us at 800-397-3429, or email: sales@mprcseals.com