Industrial News: Reflecting on a great 2022 FEW Show

Leave a Comment

A look back at the 2022 Fuel Ethanol Workshop (FEW) in Minneapolis, MN

MPRC recently attended the Fuel Ethanol Workshop (FEW) in Minneapolis, MN. As a leader in innovative seal technology, the goal of exhibiting at this year’s show was for MPRC to continue to increase awareness of our current presence in the Industrial and Ethanol Industry, and showcase how we serve both the producers and equipment manufacturers of these industries.

This was the first time that MPRC exhibited at this particular event, and we are thrilled with the response and turnout we had at our booth. We take great pride in working with the individuals in this unique, hard-working industry, and are proud to assist them and help keep them running.

FUN FACTS: There are nearly 200 Ethanol Plants (195 to be exact at this time) across the United States. MPRC proudly serves well over half of the Top 10 largest Ethanol facilities with Industrial and fluid sealing components.

P.S.: To show his loyalty and appreciation for this Industry, Dave brought home a Trackmobile to drive back and forth to work! (We’re kidding of course, but it’s a fun picture! :)

Gasket Materials and Understanding Choices through ASTM Tests

Leave a CommentGasket Materials and Understanding Choices for gasket selection through ASTM Tests

Today’s blog will be posted below in print and is also available as a video here:

So many good competitors…so many good materials. It adds to the dilemma in picking who to work with and even more importantly, what to work with when picking designs and materials for seals. We use the term “seals” broadly here to include all types of seals; die-formed packing rings, cut gaskets, o-rings, hydraulic packing, you name it…all are seals.

Our owner and CEO, Mr. Robb Ridgway, remembers back in the mid-70s when two really exciting new materials hit the market. Expanded PTFE and exfoliated graphite. These products changed the fluid sealing industry in many ways, and yet, there are still a lot of people who resist them even today, more to a lack of understanding of them and their potential to eliminate sealing problems.

Some companies, including us to some degree, promote gasket materials that have great “crush resistance” under heavy loads and higher temperatures. A valid point as we have seen applications where mechanical or virgin grade PTFE gaskets as an example, have extruded or cold-flowed under constant load and temperature over an extended period, leading to leaking and eventual re-torque until the gasket fails and needs to be replaced. A material with high “crush resistance”, creeps, or cold-flows only slightly, has high torque retention and requires less maintenance time.

The new expanded PTFE materials are interesting because they resist creep / cold-flow much better and are also engineered with different types of fillers to take even great loads, having higher torque retention and again, reducing maintenance time. Exfoliated graphite gaskets, when installed, compress more but when under operating load and temperature, resists creep / cold-flow extremely well and require little maintenance time because of very high torque retention.

All of this becomes important when trying to decide on a material of choice for the application you may be working on. We don’t want to be pushing material at this point but rather some of the terms that we like to promote, to help the decision-maker better understand what is important in making the choice. We believe you will find these helpful. They are not all of the tests, but these are key in trying to make a decision. Comments – questions??? Please let us know in the comments section or by emailing our team at: sales@mprcseals.com.

Next, we want to move into some of the standardization of physical characteristics for gaskets and materials:

STANDARDIZATION OF PHYSICAL CHARACTERISTICS

SEALABILITY

Sealability is measured according to the ASTM F37 specifications. It is an indication of the material sealing ability under a set of conditions; A seating stress of 2000 psi is imposed through the flanges on the material sealing iso-octane at an internal pressure of 14.7 psi. The test is done at ambient temperature and the number shown is the amount of leakage in milliliters per hour. A lower number would generally indicate a better material.

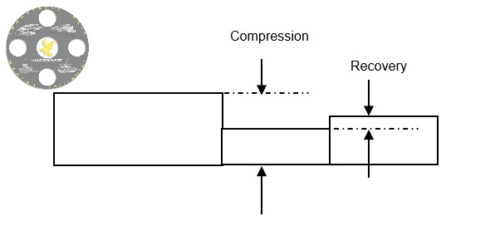

COMPRESSIBILITY

Compressibility is measured according to the ASTM F36A specification. A load of 5,000 psi is imposed on the material and the loss of thickness is measured and expressed as a percentage of the original height. The compressibility of a material indicates, to a degree, its ability to fill flange scratches, nicks, or voids and to flow or move to assist in sealing misaligned or warped flanges. In general, the higher the number, the easier it is to seat the material.

RECOVERY

Recovery is also tested under the ASTM F36A specification. Recovery is the measured rebound or increase in thickness from the compressed measurement once the load is removed. It is written as a percentage of increase over the compressed measurement and indicates the ability of the material to resist temperature and pressure. The higher the number, the better the material is at holding torque.

CREEP RELAXATION

Creep relaxation- also referred to as Torque Retention, is measured according to the ASTM F38 specification and indicates the material’s ability to hold stress or bolt load over an extended period. It is expressed as a percentage of the original load and shows the amount of lost stress from that load. A lower number indicates a more stable material retaining torque and resisting leakage.

TENSILE STRENGTH

Tensile strength is measured under ASTM F152 and is given in pounds per square inch. It is the total force required to pull the material apart and is not related to the sealing function of the material. It relates more to the manufacturing process.

At MPRC, we have always promoted “Life Cycle Costing”. We believe it is important to try to give our customers the best material choices rather than the “cheapest” option with the lowest price just to get the order. That does no one any good. While we know that we have many good competitors, we also know that many only want the business at any cost. Usually, the customer is thrilled with the price until maintenance calls up to inquire about the material purchased that falls short of the “run-time goals”. We hope the information above will help in assessing the material choices you are working through to make an informed decision. Thank you!