Customize Mechanical Seals to Safeguard Your Pumps

MPRC can provide a wide range of mechanical seals to help minimize the risk of leaks and costly downtime in your facilities. Our seals are customized to meet the needs of your pump systems, with a selection of mechanical seal types and designs.

Here we’ll review what these seals are, their features and benefits, and how MPRC can give you what you need with top-quality seal products and services.

What Is a Mechanical Seal?

Mechanical seals are used to contain fluid inside pumps and other vessels. This containment method involves a rotating shaft that passes through a type of stationary housing, but it may also consist of a housing that rotates around the shaft. In applications requiring seals, rotating shafts need to be able to enter the pump’s “wet” area while preventing large volumes of pressurized fluid from escaping. The seal is placed between the pump housing and shaft to help contain the process pressure and hold up against the friction resulting from the rotating shaft.

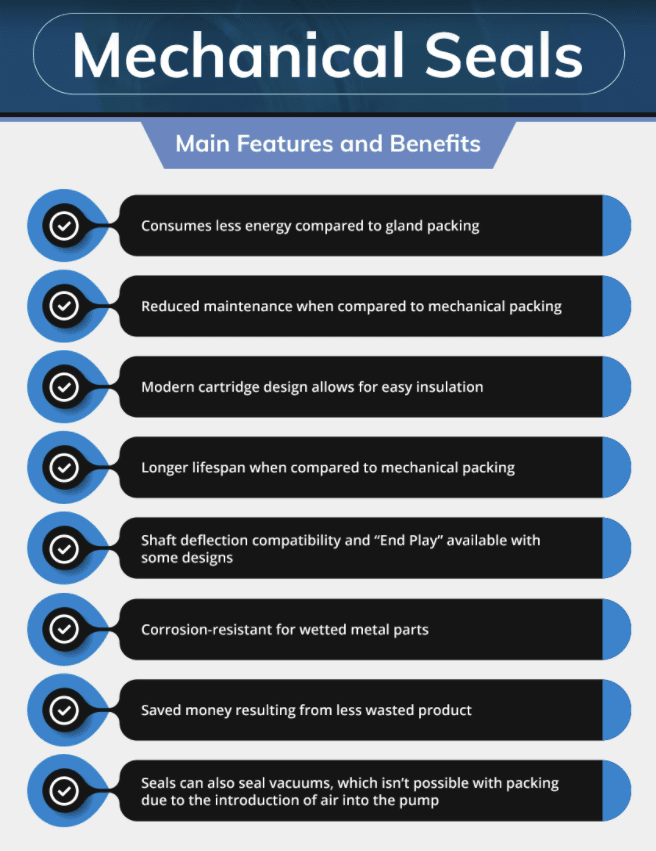

Main Features and Benefits

Mechanical pump seals come with several features and benefits, such as:

- Seals the pump shaft while enabling it to rotate

- Consumes less energy compared to gland packing

- Reduced maintenance requirements due to the use of inboard springs that self-adjust upon wear

- Minimal shaft or sleeve wear with modern cartridge seal designs Invisible leakage (only vapor)

- As long as a 20-year lifespan

- Shaft deflection compatibility and “End Play” available with some designs

- Less damage results from corrosion if the product is within the pump

- Saved money resulting from less wasted product

- Seals can also seal vacuums, which isn’t possible with packing due to the introduction of air into the pump

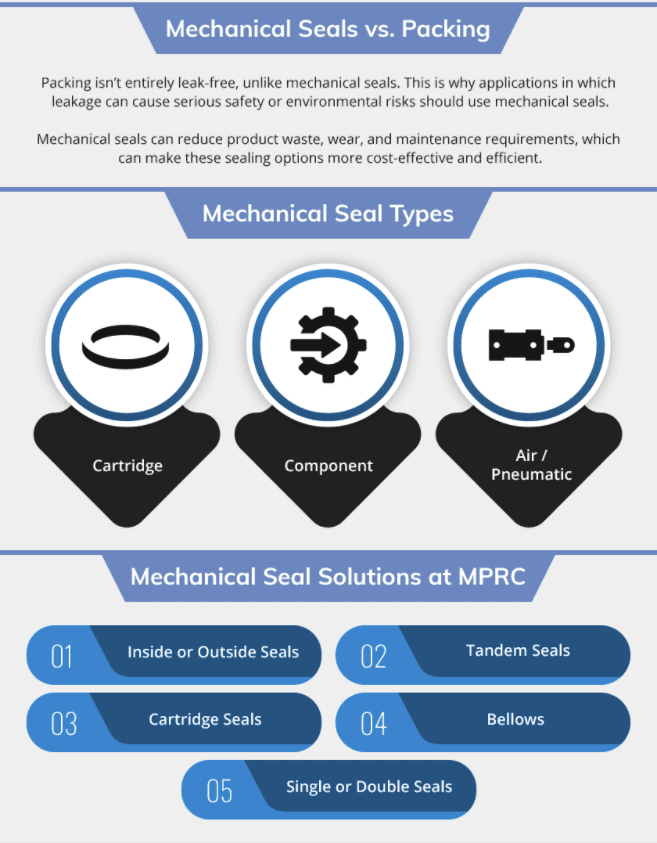

Mechanical Seals vs. Packing

Many applications use packing as a sealing solution instead of mechanical seals. However, packing isn’t entirely leak-free, unlike mechanical seals. This is why applications in which leakage can cause serious safety or environmental risks should use mechanical seals. Additionally, mechanical seals can reduce product waste, wear, and maintenance requirements, which can make these sealing options more cost-effective and efficient.

Mechanical Seal Types

There are three main types of mechanical seals available depending on the needs of a particular application. These include:

- Cartridge. These are end-face mechanical seals that are entirely self-contained, housing sealing components including hardware, sleeves, and glands. Manufacturers can preassemble and preset the seals, which helps simplify both installation and maintenance.

- Component. These end-face seals consist of a stationary seat and separate rotating member that mount in either a housing or a gland. The manufacturer doesn’t preset or preassemble these seals, which makes installation and maintenance more complex, requiring the help of technicians.

- Air. These are pneumatic devices that are non-contacting and designed to seal rotating shafts most commonly used in slurry and dry powder applications. They can minimize product loss, contamination, and emissions through the use of minute amounts of inert gas or air.

Choosing the Best Mechanical Seal Type for Your Application

When choosing a specific type of mechanical seal for your application, there are several factors to consider. If you select the wrong type of seal, your operations could suffer from decreased pump integrity, system shutdowns and downtime, and expensive repairs. Some considerations that can help you select the right seal include the type of fluid you need to pump, pump fluid pressure, temperature, and operator safety concerns.

Depending on your specific needs, the experts at MPRC can assist with seal selection.

Mechanical Seal Solutions at MPRC

At MPRC, we can provide a range of seal styles and designs based on your application’s requirements, including:

- Inside or Outside Seals

- Tandem Seals

- Cartridge Seals

- Bellows

- Single or Double Seals

All of these seals can be either balanced or unbalanced depending on your specific needs. We can also repair any type of seal. As a result, you can strengthen your workflow with dependable, high-grade custom mechanical seals that provide lasting results for many years. Regardless of what you need, we’re here to help you find the right mechanical seal solution.

Industries Served

Our seals are available for a wide range of industries, including:

- Food Processing

- Locomotive Manufacturers

- Chemical Plants

- Refineries

- Pharmaceuticals

- Rail and Marine

- After Market

- Power Plants

- Water Treatment Plants

- Pump and Valve Manufacturer

Contact Us for Custom Mechanical Sealing Solutions

For many applications, mechanical seals are the ideal solution to use for sealing pumps. MPRC is here to provide you with top-quality seals and top-tier customer sFervice, with fast response times and USA-made products. We are also backed by ISO 9001, ISD, and RSI to provide consistently reliable solutions for our customers.

To get started on a custom solution with our experts, request a quote or contact us today to tell us about your most challenging problem or application.