MPRC featured in Sept 22′ Edition of Energy Business Review Magazine

Leave a Comment

Here’s a great article highlighting the reasons to work with a manufacturer who is ISO Certified. Master Packing & Rubber Company (MPRC) is not only ISO-9001 Certified, but AAR M-1003 Certified as well. What does this mean for you, the customer? Assurance. You can rest assured that as a gasket manufacturer, MPRC will work to continuously improve upon our processes, attacking any problems that may arise to ensure they do not happen again. Ultimately, the goal is to make our organization better, more accountable, and provide the best possible service to our customers.

https://www.mcl.bz/blog/reasons-to-work-with-an-iso-certified-supplier

The “Ladder Gasket” from MPRC

Master Packing & Rubber Company (MPRC) takes great pride in “thinking outside the box” to do whatever it takes to assist our customers, and we never shy away from challenging or problem applications that many suppliers turn down.

One example of a solution we provided our customer is a fully-molded “Ladder gasket,” which goes inside a large rotating drum. The previous OEM version was not only failing after limited use, but the lead time to acquire a new seal was excessive. This made the overall replacement cost and down-time while waiting for new parts a losing effort.

MPRC was able to fully-mold this gasket in house thanks to our customer sending us the actual drum that the gasket fits in to ensure a precision fit, resulting in proper sealing. In addition, MPRC determined the best material needed for the application based on temperature, pressure, rotation, and media the material seals against. The result: an improved seal that exceeds OEM standards, improves service life, and provides a cost savings to the customer with drastically improved lead times.

The MPRC “Ladder Gasket” is just one example of the many custom molded seals that MPRC offers our customers. Contact us at 800-397-3429 to see how we can assist you with your application!

A look back at the 2022 Fuel Ethanol Workshop (FEW) in Minneapolis, MN

MPRC recently attended the Fuel Ethanol Workshop (FEW) in Minneapolis, MN. As a leader in innovative seal technology, the goal of exhibiting at this year’s show was for MPRC to continue to increase awareness of our current presence in the Industrial and Ethanol Industry, and showcase how we serve both the producers and equipment manufacturers of these industries.

This was the first time that MPRC exhibited at this particular event, and we are thrilled with the response and turnout we had at our booth. We take great pride in working with the individuals in this unique, hard-working industry, and are proud to assist them and help keep them running.

FUN FACTS: There are nearly 200 Ethanol Plants (195 to be exact at this time) across the United States. MPRC proudly serves well over half of the Top 10 largest Ethanol facilities with Industrial and fluid sealing components.

P.S.: To show his loyalty and appreciation for this Industry, Dave brought home a Trackmobile to drive back and forth to work! (We’re kidding of course, but it’s a fun picture! :)

Gasket Materials and Understanding Choices for gasket selection through ASTM Tests

Today’s blog will be posted below in print and is also available as a video here:

So many good competitors…so many good materials. It adds to the dilemma in picking who to work with and even more importantly, what to work with when picking designs and materials for seals. We use the term “seals” broadly here to include all types of seals; die-formed packing rings, cut gaskets, o-rings, hydraulic packing, you name it…all are seals.

Our owner and CEO, Mr. Robb Ridgway, remembers back in the mid-70s when two really exciting new materials hit the market. Expanded PTFE and exfoliated graphite. These products changed the fluid sealing industry in many ways, and yet, there are still a lot of people who resist them even today, more to a lack of understanding of them and their potential to eliminate sealing problems.

Some companies, including us to some degree, promote gasket materials that have great “crush resistance” under heavy loads and higher temperatures. A valid point as we have seen applications where mechanical or virgin grade PTFE gaskets as an example, have extruded or cold-flowed under constant load and temperature over an extended period, leading to leaking and eventual re-torque until the gasket fails and needs to be replaced. A material with high “crush resistance”, creeps, or cold-flows only slightly, has high torque retention and requires less maintenance time.

The new expanded PTFE materials are interesting because they resist creep / cold-flow much better and are also engineered with different types of fillers to take even great loads, having higher torque retention and again, reducing maintenance time. Exfoliated graphite gaskets, when installed, compress more but when under operating load and temperature, resists creep / cold-flow extremely well and require little maintenance time because of very high torque retention.

All of this becomes important when trying to decide on a material of choice for the application you may be working on. We don’t want to be pushing material at this point but rather some of the terms that we like to promote, to help the decision-maker better understand what is important in making the choice. We believe you will find these helpful. They are not all of the tests, but these are key in trying to make a decision. Comments – questions??? Please let us know in the comments section or by emailing our team at: sales@mprcseals.com.

Next, we want to move into some of the standardization of physical characteristics for gaskets and materials:

SEALABILITY

Sealability is measured according to the ASTM F37 specifications. It is an indication of the material sealing ability under a set of conditions; A seating stress of 2000 psi is imposed through the flanges on the material sealing iso-octane at an internal pressure of 14.7 psi. The test is done at ambient temperature and the number shown is the amount of leakage in milliliters per hour. A lower number would generally indicate a better material.

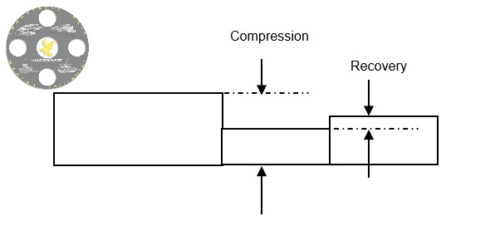

COMPRESSIBILITY

Compressibility is measured according to the ASTM F36A specification. A load of 5,000 psi is imposed on the material and the loss of thickness is measured and expressed as a percentage of the original height. The compressibility of a material indicates, to a degree, its ability to fill flange scratches, nicks, or voids and to flow or move to assist in sealing misaligned or warped flanges. In general, the higher the number, the easier it is to seat the material.

RECOVERY

Recovery is also tested under the ASTM F36A specification. Recovery is the measured rebound or increase in thickness from the compressed measurement once the load is removed. It is written as a percentage of increase over the compressed measurement and indicates the ability of the material to resist temperature and pressure. The higher the number, the better the material is at holding torque.

CREEP RELAXATION

Creep relaxation- also referred to as Torque Retention, is measured according to the ASTM F38 specification and indicates the material’s ability to hold stress or bolt load over an extended period. It is expressed as a percentage of the original load and shows the amount of lost stress from that load. A lower number indicates a more stable material retaining torque and resisting leakage.

TENSILE STRENGTH

Tensile strength is measured under ASTM F152 and is given in pounds per square inch. It is the total force required to pull the material apart and is not related to the sealing function of the material. It relates more to the manufacturing process.

At MPRC, we have always promoted “Life Cycle Costing”. We believe it is important to try to give our customers the best material choices rather than the “cheapest” option with the lowest price just to get the order. That does no one any good. While we know that we have many good competitors, we also know that many only want the business at any cost. Usually, the customer is thrilled with the price until maintenance calls up to inquire about the material purchased that falls short of the “run-time goals”. We hope the information above will help in assessing the material choices you are working through to make an informed decision. Thank you!

The M-Nozzle™ Gasket from MPRC.

When it comes to Railcar Manway gaskets, let’s face it: there are too many sizes, thicknesses, and variations to keep track of. How can you tell the difference between a gasket that’s supposed to be 21” x 19” versus a gasket of similar color that’s 21 1/4” x 18 7/8”? In addition, supplier lead times are at an all-time high, making some Railcar gaskets very difficult to get your hands on. So, how do you get the gaskets you need promptly?

It’s frustrating, and we get it. That’s why MPRC developed a simplified solution: One gasket that fits over any standard 20” Nozzle that replaces manway or “top hatch” cover gaskets. The M-Nozzle™ Gasket from MPRC. One Gasket- One Answer- ONE SOLUTION.

Reduce inventory and enjoy the benefits of easier gasket installation and safer gasket removal with the fully molded M-Nozzle™ gasket from MPRC. Made in-house at our Cedar Rapids, IA headquarters, the M-Nozzle™ gasket is supplied in Black Nitrile, White FDA Nitrile, and Blue EPDM, covering general service, food sweeteners, and Ethanol and petroleum products. Just slip on and off the nozzle, and the unique design will clamp and hold the gasket in place.

We have a large selection of M-Nozzle™ gaskets in stock and ready for shipment. Call MPRC today at 800-397-3429 and let us assist you with your Railcar Fleet.

MPRC’s M-Nozzle™ Gasket available in Black Nitrile, White FDA Nitrile, and Blue EPDM.

***SPOILER ALERT: MPRC is working on a new Yellow Viton “B” M-Nozzle gasket at this time (shown below) that we hope to have available for release in the very near future, as we continue to navigate through material shortages and excessive lead times for all Viton materials. Stay tuned for more updates!***

MPRC Employee Spotlight: Sebastian Struchen, Shipping Manager

Sebastian (aka “Sea-bass”) is MPRC’s Shipping Manager. Sebastian has been with MPRC for 7 ½ years and is a tremendous asset to our team. Thanks to his leadership and the efforts of our shipping department, you can rest assured your order will get to you as quickly as possible.

In his free time, Sebastian enjoys golfing and watching sports with friends. His favorite teams are the Green Bay Packers, Chicago Cubs, Boston Celtics, and Iowa Hawkeyes. Sebastian is also a 5-time Fantasy Football loser- LOL!

He may have a great sense of humor, but it’s serious business when it comes to shipping orders to our valued customers. We appreciate all that you do, Sebastian!

Patrick (Pat) Silvey

VP of Technical Service & Sales

Joined Master Packing, 2017

Not only is Pat a valuable asset to us here at MPRC in his role as VP of Technical Service and Sales at MPRC, but he can hold the beat down and lay down some serious notes on the skins too. Pat’s been a drummer for years, and best describes himself as “A musician that’s dedicated all percussive efforts to guiding many secondary instrumentalists like guitar and bass players to sound better. Maybe a singer or two — although I have great respect for piano players, they are at the top of the heap of secondary instrumentalists. Needless to say, drums rule!”

Pat started his diesel engine career in the 1970s working within the rail and marine industry. Much of his mechanical knowledge has been gained through hands-on experiences that have enabled him to understand the mechanical complexities that port engineers and chief mechanical officers face on a daily basis.

Through the years, Pat has done an incredible job assisting customers in acquiring parts best suited for their applications. MPRC can assure you that if you’ve called us for assistance in obtaining a correct part number or need reassurance that what you are purchasing is the correct part for the engine application, Pat has most certainly had something to do with providing that service.

Pat is an absolute joy to work with, and we joke internally that he’s our “resident mechanic.” And although the truth is he wasn’t one “officially,” you’d never know otherwise. Pat set himself apart from the pack by paying close attention to the real field and service mechanics that he assisted in engine rebuilding and problem-solving. This close attention to detail has translated beautifully into a very technical sales role that is tremendously valuable to the team at MPRC and how we serve our customers as fluid sealing specialists.

MPRC Bio-Fuel Test

To cover our recent test and findings, we need to briefly identify what a Bio-Fuel is:

Bio-Fuels- unlike other renewable energy sources, come from biomass such as plant or animal waste. A Bio-Fuel comes from the conversion of this waste into a liquid fuel, used to meet transportation fuel needs. There are two common types of Bio-Fuels: Ethanol and Bio-Diesel.

Ethanol: A Bio-fuel as it is normally made from corn, although sugar cane is also used, mostly in South America. Blended with gasoline, it increases octane and cuts down carbon monoxide and other smog-causing emissions.

Bio-Diesel: Combined with alcohol, it is a liquid fuel produced from renewable sources such as new and used vegetable oils and animal fats or cooking grease, and is a cleaner-burning replacement for petroleum-based diesel fuel. It’s also non-toxic and biodegradable, and is a cleaner-burning fuel than diesel, eliminating much of the particulate matter that goes out of the exhaust including hydrocarbons, carbon monoxide, and others. Bio-fuels also give a cleaner burn over regular gas, although they do emit about the same amount of CO2 as gas.

Simply put- you can’t use just any O-ring or rubber material when it comes to Bio-Fuels. For example, the aggressive, contaminated Bio-fuel attacks hydrocarbon rubbers such as nitrile rubber, widely used in fuel handling hose, gaskets, and seals. MPRC recommends selecting a Viton Fluoro-Hydrocarbon Elastomer (FKM) for Bio-Fuel service. Of all the testing of various Viton compounds in Bio-Fuels, results have shown that Viton has excellent compatibility with Bio-Diesel (both fresh and contaminated), and has a high resistance to permeation and chemical attack by alcohol, pure ethanol, and blends of ethanol with hydrocarbon fuel.

Just the other day, the team at MPRC was discussing Bio-Fuels and the effect that Bio-Fuels have on Elastomers. Then I remembered something really neat that we did years ago, that I hoped was still around- somewhere. Much to my surprise, it was!

In 2008, we started a test on some O-rings and grommets designed and formulated in our yellow Viton “B” compound. We had acquired some Bio-Diesel from a local company that is unfortunately no longer in business, but they used to offer classes on how to produce Bio-Diesel and even sold equipment to do so.

We decided to place two of our head gasket grommets and a few O-rings into the Bio-Diesel and let it sit- and that we did. I had for the most part forgotten about this, but our discussion earlier this week made me remember. Finally, after sitting in a jar for that long, it was time to remove the items and see how they measured up against the Bio-Diesel.

I don’t know a whole lot of products these days that can say they’ve held up to something like a Bio-Diesel for 14 years- but ours did!

Here are our specific findings:

After removing each item from the Bio-Diesel jar, we carefully inspected and checked the dimensional tolerances. MPRC carefully checked the inner and outer diameter of each item in addition to the overall hardness of each material. To our surprise, ALL of the items remained well within the proper dimensional tolerance/spec. Not only that, but on a few of the items, you can still see the “MPRC” that is raised and embossed into the molded ring very clearly and without any distortion. NOTE: There is a small chunk taken out of the more faded yellow grommet. This is not due to anything relating to Bio-Diesel. MPRC removed a small piece of the grommet to send for testing and lab analysis on the original compound.

Call us hoarders of our precious little Bio-Diesel container, but we like to think of ourselves as brilliant scientists who have made an incredible breakthrough. We’re kidding, of course. We think we do a pretty good job of being fluid sealing specialists, however, and doing fun little science experiments like this to see how our products hold up is a lot of fun. Call us today and see how we can assist you with your fluid sealing needs!

800-397-3429

sales@mprcseals.com

**References: “Biofuel Basics”– Office of Energy Efficiency & Renewable Energy, Bioenergy Technologies Office**

In the Engine business, most gaskets fail due to a combination of thermal cycling and improper surface preparation. Surfaces can become scratched, warped, or pitted which doesn’t allow for equal compression on the sealing surface, increasing the failure rate of the material.

Many people spend a lot of time searching for the perfect gasket material that they’re told “will do X” or “won’t do” (fill in the blank). When it comes to gasket swelling, however, here’s the thing: ALL GASKETS SWELL to some extent.

There are a lot of companies in the fluid sealing industry that don’t want consumers to know that gaskets actually swell. Others use the occurrence of swelling as a material selling point. At MPRC, our goal is to be your fluid sealing specialist, and we strive to educate our customers on the best-suited materials for their specific applications.

There’s also the question of HOW a gasket is installed. Is the gasket being installed dry, or is there a lubricant that is applied to the sealing surface or the gasket directly? That answer will have a tremendous effect on the service life and performance of the gasket.

MPRC recommends installing our gaskets dry- that is, “as-is” without any RTV Silicone or lubricant added. It is important to remember the friction between a gasket and the flanges must be maintained to create a long-lasting seal. Any wet Silicone or oil destroys that friction and most gasket materials will extrude under load. We do recommend or suggest using a Permatex Aviation Grade adhesive or a 3M #77 adhesive to hold a gasket in place, particularly on vertical applications to help the mechanic by holding it in the place where needed. RTV Silicone applied wet will off-gas volatiles that will compromise the integrity of the elastomers in a gasket and lead to premature gasket failure.

(The gaskets that are shown below- LEFT side, were installed dry and used in test service. The gaskets on the RIGHT were installed using RTV Silicone and used in test service)

MPRC has a series of material designations for a wide variety of engine and exhaust applications within the Rail and Marine Industries. We offer CG1 (our OEM Grade), CG2 (our upgrade), and CGO (our Optimized grade). Each option represents a quality sealing solution based upon a specific price point.

CG1 (off-white) offers a high-temp sealing option to 400°F continuous and 700°F maximum, which is affordable. Some applications do not require the “best of the best” when it comes to material and price points, which makes CG1 a very cost-effective solution.

CG2 (yellow one side/grey opposing side) is another high-temp sealing solution that offers a slightly higher temp rating to 662°F and maximum at 845°F. This material is an upgrade from the standard OEM grade material.

For more product info, please contact us at 800-397-3429 or email our sales team at: sales@mprcseals.com

SPOILER ALERT!!!!

**MPRC will be releasing our 7th Generation of Style 7800 gasket material after further testing is completed. Stay tuned for more updates!**