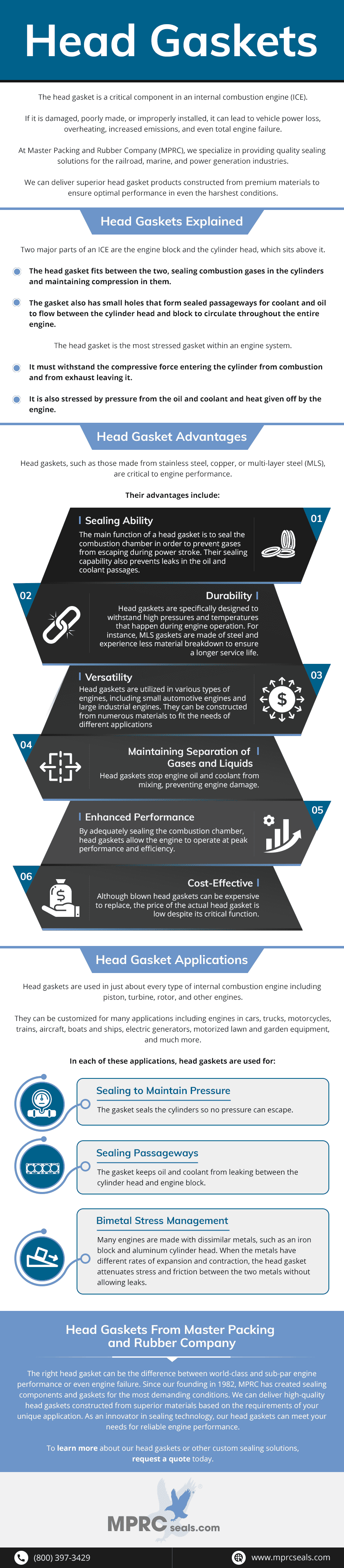

The head gasket is a critical component in an internal combustion engine (ICE). If it is damaged, poorly made, or improperly installed, it can lead to vehicle power loss, overheating, increased emissions, and even total engine failure. At Master Packing and Rubber Company (MPRC), we specialize in providing quality sealing solutions for the railroad, marine, and power generation industries. We can deliver superior head gasket products constructed from premium materials to ensure optimal performance in even the harshest conditions.

Head Gaskets Explained

Two major parts of an ICE are the engine block and the cylinder head, which sits above it. The head gasket fits between the two, sealing combustion gases in the cylinders and maintaining compression in them. The gasket also has small holes that form sealed passageways for coolant and oil to flow between the cylinder head and block to circulate throughout the entire engine.

The head gasket is the most stressed gasket within an engine system. It must withstand the compressive force entering the cylinder from combustion and from exhaust leaving it. It is also stressed by pressure from the oil and coolant and heat given off by the engine.

Head Gasket Advantages

Head gaskets, such as those made from stainless steel, copper, or multi-layer steel (MLS), are critical to engine performance. Their advantages include:

- Sealing ability: The main function of a head gasket is to seal the combustion chamber in order to prevent gases from escaping during power stroke. Their sealing capability also prevents leaks in the oil and coolant passages.

- Durability: Head gaskets are specifically designed to withstand high pressures and temperatures that happen during engine operation. For instance, MLS gaskets are made of steel and experience less material breakdown to ensure a longer service life.

- Versatility: Head gaskets are utilized in various types of engines, including small automotive engines and large industrial engines. They can be constructed from numerous materials to fit the needs of different applications.

- Maintaining separation of gases and liquids: Head gaskets stop engine oil and coolant from mixing, preventing engine damage.

- Enhanced performance: By adequately sealing the combustion chamber, head gaskets allow the engine to operate at peak performance and efficiency.

- Cost-effective: Although blown head gaskets can be expensive to replace, the price of the actual head gasket is low despite its critical function.

Head Gasket Applications

Head gaskets are used in just about every type of internal combustion engine including piston, turbine, rotor, and other engines. They can be customized for many applications including engines in cars, trucks, motorcycles, trains, aircraft, boats and ships, electric generators, motorized lawn and garden equipment, and much more.

In each of these applications, head gaskets are used for:

- Sealing to maintain pressure: The gasket seals the cylinders so no pressure can escape.

- Sealing passageways: The gasket keeps oil and coolant from leaking between the cylinder head and engine block.

- Bimetal stress management: Many engines are made with dissimilar metals, such as an iron block and aluminum cylinder head. When the metals have different rates of expansion and contraction, the head gasket attenuates stress and friction between the two metals without allowing leaks.

Head Gaskets From Master Packing and Rubber Company

The right head gasket can be the difference between world-class and sub-par engine performance or even engine failure. Since our founding in 1982, MPRC has created sealing components and gaskets for the most demanding conditions. We can deliver high-quality head gaskets constructed from superior materials based on the requirements of your unique application. As an innovator in sealing technology, our head gaskets can meet your needs for reliable engine performance.

To learn more about our head gaskets or other custom sealing solutions, request a quote today.