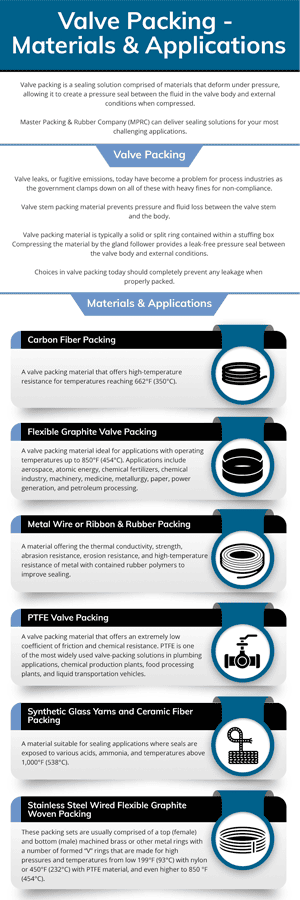

Valve packing is a sealing solution comprised of materials that deform under pressure, allowing it to create a pressure seal between the fluid in the valve body and external conditions when compressed. Master Packing & Rubber Company (MPRC) can deliver sealing solutions for your most challenging applications.

Valve Packing

Valve leaks, or fugitive emissions, today have become a problem for process industries as the government clamps down on all of these with heavy fines for non-compliance. Valve stem packing material prevents pressure and fluid loss between the valve stem and the body. Valve packing material is typically a solid or split ring contained within a stuffing box. Compressing the material by the gland follower provides a leak-free pressure seal between the valve body and external conditions. Choices in valve packing today should completely prevent any leakage when properly packed.

Materials & Applications

At MPRC, we offer several packing options to suit various applications. Our material options include:

- Carbon Fiber Packing: A valve packing material that offers high-temperature resistance for temperatures reaching 662°F (350°C).

- Flexible Graphite Valve Packing: A valve packing material ideal for applications with operating temperatures up to 850°F (454°C). Applications include aerospace, atomic energy, chemical fertilizers, chemical industry, machinery, medicine, metallurgy, paper, power generation, and petroleum processing.

- Metal Wire or Ribbon & Rubber Packing: A material offering the thermal conductivity, strength, abrasion resistance, erosion resistance, and high-temperature resistance of metal with contained rubber polymers to improve sealing.

- PTFE Valve Packing: A valve packing material that offers an extremely low coefficient of friction and chemical resistance. PTFE is one of the most widely used valve-packing solutions in plumbing applications, chemical production plants, food processing plants, and liquid transportation vehicles.

- Synthetic Glass Yarns and Ceramic Fiber Packing: A material suitable for sealing applications where seals are exposed to various acids, ammonia, and temperatures above 1,000°F (538°C).

- Stainless Steel Wired Flexible Graphite Woven Packing: These packing sets are usually comprised of a top (female) and bottom (male) machined brass or other metal rings with a number of formed “V” rings that are made for high pressures and temperatures from low 199°F (93°C) with nylon or 450°F (232°C) with PTFE material, and even higher to 850 °F (454°C).

Packing Services From MPRC

Valve stem packing material can be a solid or deformable material that is compressed by pressure by the gland follower, to prevent fluids within the valve from leaking and creating dangerous external conditions where people can suffer from hot liquid sprays and drips. MPRC uses several valve packing materials, such as PTFE, graphite, and synthetic fibers, to provide solutions for various applications, including high-temperature and corrosive applications.

MPRC has over 40 years of experience delivering solutions for the most challenging sealing applications. We offer custom gaskets and seals, mechanical seals for pumps, mechanical packing for valves and pumps, hydraulic and pneumatic seals and packing, and flex-tex expanded PTFE joint sealant products. Request a quote to learn more about our valve packing solutions.