Expanded PTFE Products for Enhanced Chemical Resistance

Easy-to-Apply, Versatile Joint Sealant

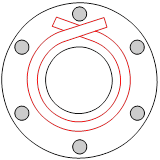

Flex-tex expanded PTFE is your go-to sealant in maintenance, especially when emergencies come up. This flange sealant is a soft, compressible gasketing material made of 100% pure, expanded PTFE available with an adhesive strip for easy application. It comes in a number of forms, including ribbon, tape, or valve stem packing.

Flex-tex expanded PTFE is your go-to sealant in maintenance, especially when emergencies come up. This flange sealant is a soft, compressible gasketing material made of 100% pure, expanded PTFE available with an adhesive strip for easy application. It comes in a number of forms, including ribbon, tape, or valve stem packing.

With “flex” in its name, you can be sure that this sealant will be flexible to your needs and industrial equipment. It is a form-in-place gasket that conforms to virtually any sealing surface. Flex-tex meets FDA requirements and offers guaranteed strength, resistant to common chemicals, and is rated for temperatures from -400°F to 550°F compared to any other soft gasket. Strength and durability is guaranteed in the Flex-tex joint sealant. Upon compression, it forms a thin, hard ribbon that fills in surface irregularities and creates an extremely tight seal. It has a high resistance to cold flow, unlike most “hard” sheet PTFE. Avoid downtime and seal-proof your manufacturing and facility equipment by using Flex-Tex sealant for your maintenance needs.