Gaskets fill the gap between the surfaces of two parts, joining them and creating an effective seal that prevents leakage. Manufacturers have multiple methods for producing various types of high-quality gaskets, depending upon the material selection, available equipment, and application requirements.

Two common options are cut gaskets, which manufacturers cut from sheets of raw material, and molded gaskets, which are the product of one of several molding processes. Learn more about the unique advantages and proper applications of each type to help you choose the right option to fulfill your gasket needs.

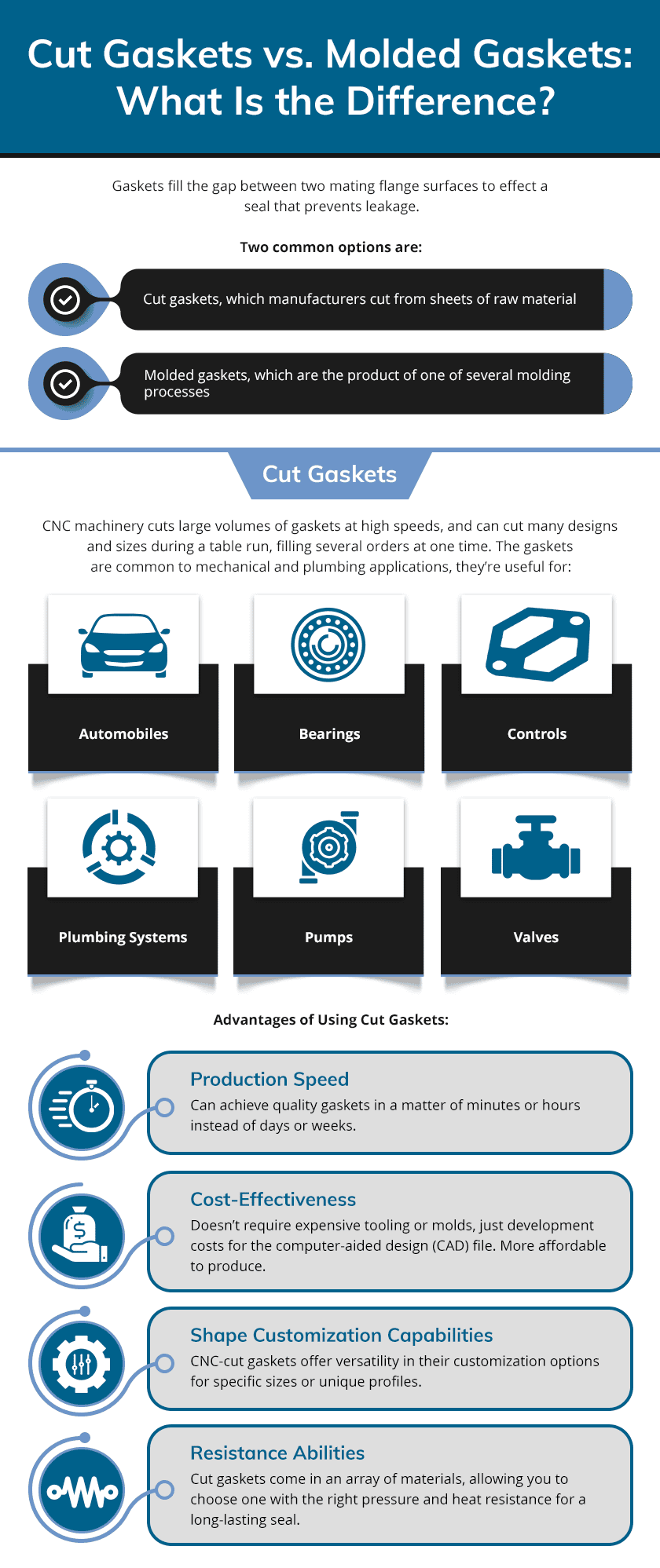

Cut Gaskets Explained

From a sheet of material, CNC machinery cuts large volumes of components at high speeds, producing identical gaskets. They sit between two surfaces and create a tight seal through compressive force, filling any space caused by unevenness, gaps, or imperfections on those surfaces to make up for any design flaws. With common mechanical and plumbing applications, they’re useful for:

- Automobiles

- Bearings

- Controls

- Plumbing systems

- Pumps

- Valves

Advantages of Using Cut Gaskets

Some of the key advantages of CNC-cut gaskets include:

- Production speed. As you won’t need to first create a custom die to generate your gaskets with die-less gasket cutting, you can achieve quality gaskets in a matter of minutes or hours rather than the process taking days or even weeks.

- Cost-effectiveness. CNC-cut gaskets don’t require expensive tooling or molds, just development costs for the computer-aided design (CAD) file to guide the cutting process. This process makes cut gaskets more affordable to produce than using alternate techniques.

- Shape customization capabilities. When you need gaskets in specific sizes or unique profiles, CNC-cut gaskets offer versatility in their customization options.

- Resistance abilities. Equipment systems commonly utilize hot fluids, meaning gaskets must withstand high temperatures and pressures. Cut gaskets come in an array of materials, allowing you to choose one with the right pressure and heat resistance for a long-lasting seal.

Molded Gaskets Explained

Molded gaskets offer more complex and versatile designs. First, manufacturers build a precision mold with a cavity in the shape of the desired gasket. Then they fill the cavity with a plastic, rubber, or other uncured elastomer substrate where, through heat and pressure, the material sets and cures, retaining the mold’s shape.

Three common techniques for producing molded gaskets are:

- Injection molding. The fastest of the molding processes, injection molding produces highly consistent gaskets that minimize or eliminate the need for secondary finishing or trim work due to their optimal surface finish without flashing.

- Compression molding. Manufacturers turn to compression molding to generate large-sized molded gaskets. It’s a cost-effective method with low mold and per-part costs, and it produces little unreusable waste.

- Transfer molding. This process is relatively fast and, compared to compression molding, transfer molding offers enhanced uniformity in gaskets. It’s well-suited to manufacturing molded rubber-to-metal components.

Advantages of Using Molded Gaskets

While there are tooling costs that accompany the molding process, molded gaskets offer a range of benefits, including:

- Enhanced design options. Using custom molds, you can generate three-dimensional gaskets, integrate additional parts into your mold’s design, create parts with varying cross-sections, incorporate engraving, and more.

- Dimensional accuracy. Molded gaskets offer tighter tolerances than cut gaskets, particularly where thickness is concerned. They create a secure bond between surfaces while enabling joint flexibility.

- Improved leakage protection. Molded gaskets don’t have splices, creating fewer opportunities for leakage.

- Minimal waste. Molding generates little material waste, which equates to the added benefit of per-part cost reductions.

Gaskets We Offer

At MPRC, we offer a wide range of gaskets and manufacturing options to suit your needs, including:

- Molded gaskets. Through injection, compression, or transfer molding, molded gaskets form through heat and pressure, offering design freedom, high performance, and close tolerances.

- Lathe-cut gaskets. A CNC lathe turns a tube of material on a mandrel against a tool to cut material away and achieve completed, structurally stable gaskets in the desired shape.

- Extruded gaskets. Elastomeric polymers like uncured rubber are forced through an extrusion die before being cut into the appropriate dimensions, taking the shape — be it simple or complex — of the die.

- Spliced gaskets. These gaskets start as extruded of material cut into specific lengths, after which the ends bond together through heat and/or adhesives for strong joints.

- Metal gaskets. Formed or cut from large sheets of metal or alloys, these highly durable gaskets create a tight seal with good pressure and chemical resistance capabilities.

- Die-cut gaskets. Using a premade die and any of several die-cutting processes, you can cut gaskets with tight tolerances out of a sheet of material.

Find the Gaskets You Need With MPRC

Master Packing and Rubber Company (MPRC) is a leading provider of seals, gaskets, and mechanical packing materials, with USA-made products for clients across the globe. Contact us today to learn more about what type of gasket is the right fit for your next project or to start your order.