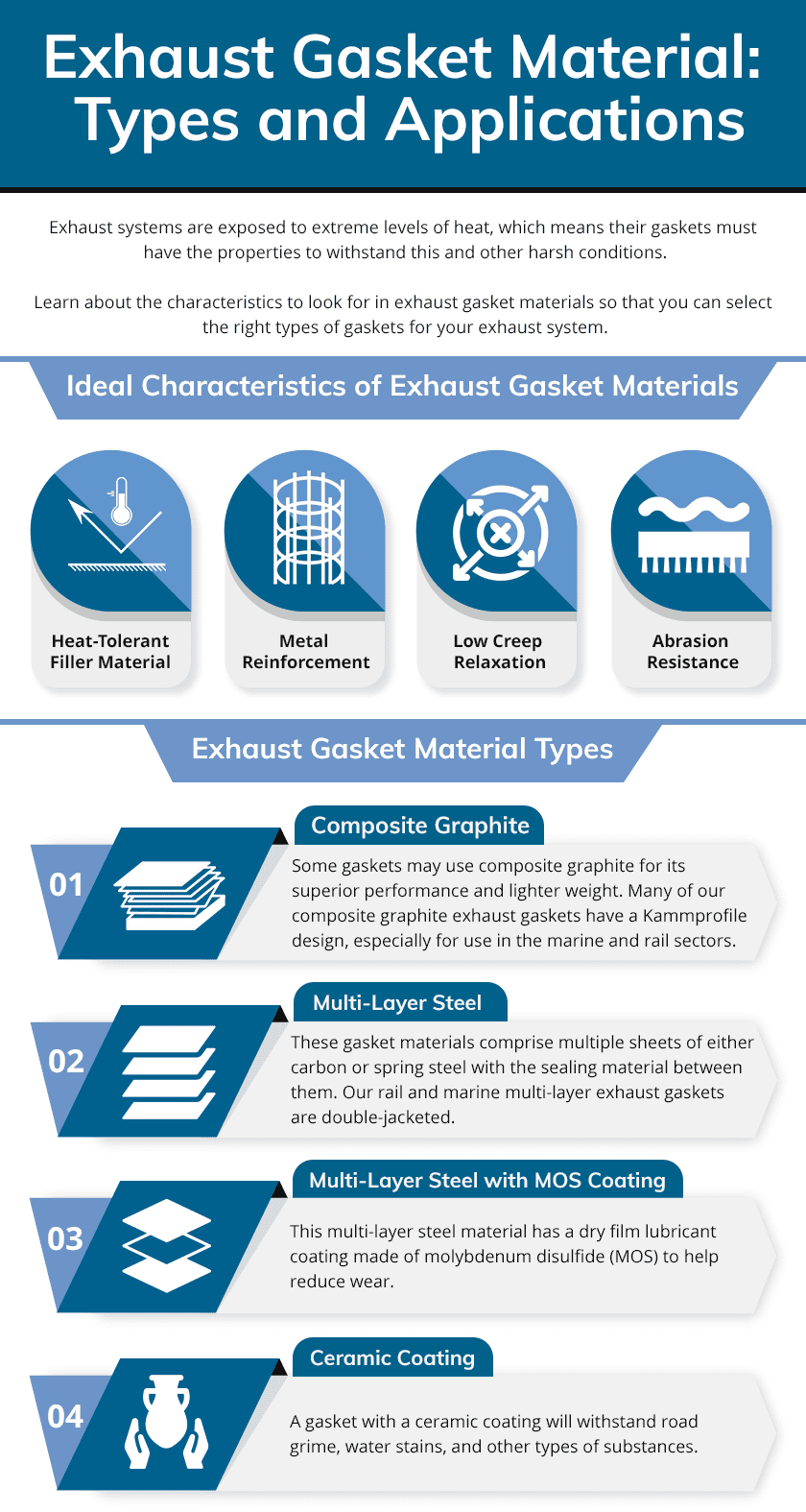

Exhaust systems are exposed to extreme levels of heat, which means their gaskets must have the properties to withstand this and other harsh conditions. Learn about the characteristics to look for in exhaust gasket materials so that you can select the right types of gaskets for your exhaust system.

Ideal Characteristics of Exhaust Gasket Materials

The following are some of the specific characteristics to look for in exhaust gasket material types.

Heat-Tolerant Filler Material

The facing/filler material of the exhaust gasket must be able to handle exposure to high temperatures without any compromise in its structural integrity. Otherwise, the seal can experience premature wear and failure.

Metal Reinforcement

Gaskets with metal reinforcements will benefit from increased durability, strength, and holding power throughout their service life.

Low Creep Relaxation

Graphite filler materials give the gasket low creep relaxation. Low creep relaxation means that the gasket material won’t experience much loss in thickness over time or under exposure to extreme heat. As a result, the gasket will maintain reliable flange loading that keeps the seal intact.

Abrasion Resistance

If your exhaust system contains joints with high thermal motion—including joints made of two or more dissimilar metals with varying contraction and expansion rates under heat—you may benefit from a clad-style exhaust gasket material to resist abrasion.

Exhaust Gasket Material Types

Based on the characteristics required of your gasket material, you may select one of the following gasket material types:

- Composite graphite — Some gaskets may use composite graphite for its superior performance and lighter weight. Many of our composite graphite exhaust gaskets have a Kammprofile design, especially for use in the marine and rail sectors.

- Multi-layer steel — These gasket materials comprise multiple sheets of either carbon or spring steel with the sealing material between them. Our rail and marine multi-layer exhaust gaskets are double-jacketed.

- Multi-layer steel with MOS coating — This multi-layer steel material has a dry film lubricant coating made of molybdenum disulfide (MOS) to help reduce wear.

- Ceramic coating — A gasket with a ceramic coating will withstand road grime, water stains, and other types of substances.

- Sandwich type — These gaskets include two thin layers of aluminum, copper, steel, or another type of metal with a center layer of graphite.

Exhaust Gasket Material Applications

Our exhaust flange gasket materials are compatible with a wide range of exhaust systems from major manufacturers:

- Caterpillar: C7, C9, C10, C12, C13, C15, C27, C32, and G3500 engines

- Cummins: QSK60, IX, ISB, K38, ISX12, and QSB3.3 engines

- Detroit Diesel: S60 and DD15 engines

- Mack: E7 engines

- MTU: Series 4000, Series 396, and Series 2000 engines

- Navistar: DT466 engines

- Volvo: D12 engines

- EMD: 567, 645, and 710 engines

- Wabtec: GE 7FDL engines

Find the Best Exhaust Gasket Materials at MPRC

It’s important to find the right exhaust gasket material for your application based on the types of conditions your exhaust system experiences. At Master Packing and Rubber Company, we provide our customers with innovatively designed and manufactured gasket exhaust materials that meet the requirements of various engines.

For more information about our products and capabilities, request a quote today.